Thinley Namgay

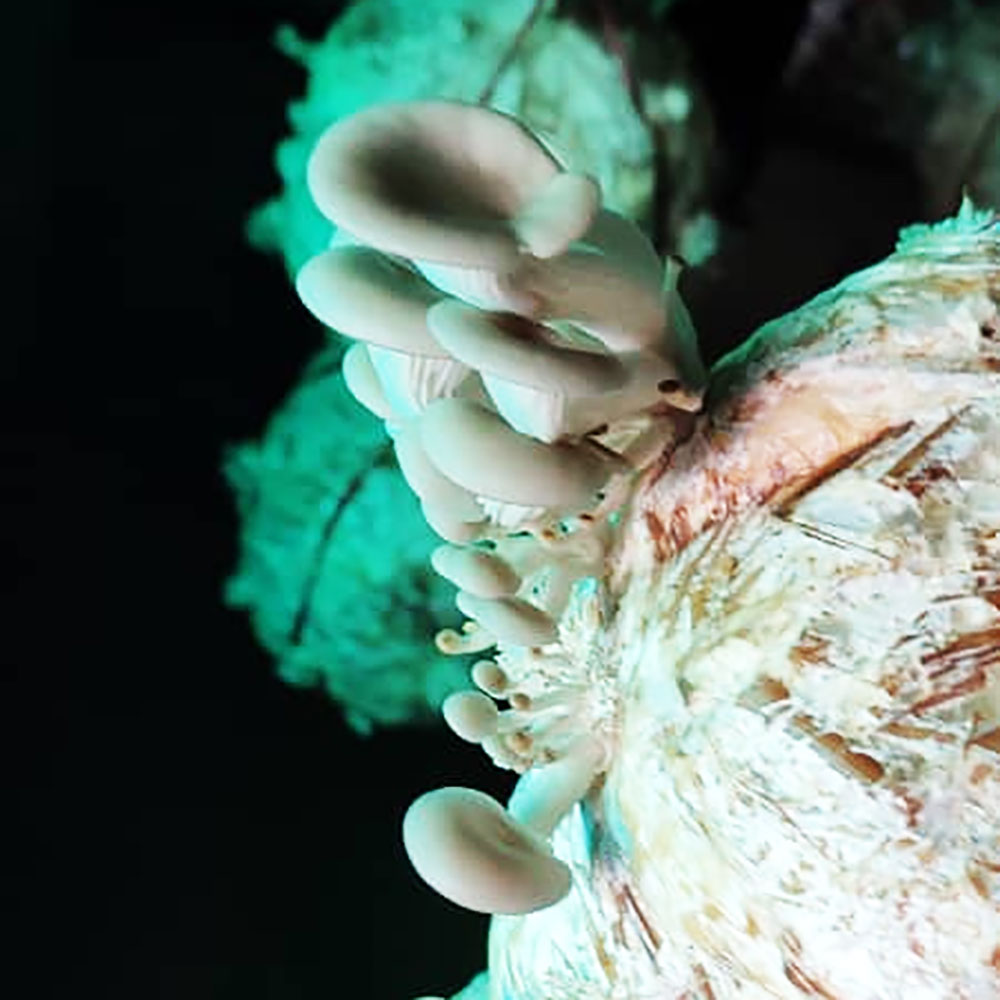

Wangsisina, Thimphu – Chencho Thinley’s mushrooms are growing well. Some are still in incubation.

Chencho Thinley is from Toebesa, Punakha. He worked in India as freelance IT personnel before he returned to Bhutan due to Covid-19 and started commercial oyster mushroom farming in July.

Chencho attended basic entrepreneurship training programme in Thimphu organised by the labour ministry and the IT Park. He availed a loan of Nu 500,000 from the national CSI bank.

Within a month, Chencho prepared 200 mushroom bags. He marketed around 30kg mushroom at Nu 400 per kg.

About 80 bags are currently in incubation.

Chencho grows grey oyster and sajor-kaju mushrooms.

Thimphu is Chencho’s primary market. There is high demand for these mushrooms.

He said that despite high demand, not many are into this business. “Cultivators mostly focus on self-consumption.”

The mushrooms need moderate temperature and clean surrounding.

To cope with both the winter and summer season demand, Chencho said he would invest in purchasing equipment such as a heater, air conditioner, and humidifier in the future.

“Otherwise, we must construct a good mushroom sheds,” Chencho said.

Oyster mushroom bag preparation is an intricate process. The whole process begins with cutting straw, soaking the straw for 20 minutes in clean water, draining the excess water and steaming the straw for more than an hour and letting the straw dry up to 80 percent.

After that, spawning starts, followed by making holes around a bag for air circulation and hanging it in a clean and dark room.

After incubation, the mushroom bag has to be cut with a clean blade in 12 to 16 places. Then you can water it regularly. Mushrooms will grow after a week and you can harvest them after a week.

Spraying water on the bag at least twice is important if the temperature is high. Water is not required during the incubation.

Mushroom seeds are bought from a wholesaler in Paro and Thimphu.

Dechen Dema, an oyster mushroom grower from Paro, said that she began the business last year after getting a loan of Nu 470,000 from the national CSI bank.

She said it was an arduous job to grow the mushroom. So far, she has made more than 1,000 mushroom bags. She also sells the bags. Prices go up to Nu 500 a bag.

“I recovered more than Nu 100,000 of loan,” said Dechen Dema.

Dechen Dema said that she could make extra income if she had a helper. Today, she is doing all the manual work herself, which she said was challenging. “Farm has to be clean. If not, bacteria will affect the bags. In summer, infection may happen due to extreme heat.”

Last month, she prepared 200 mushroom bags and sold 100. In a day, she makes about nine bags.

Karma Thinley started oyster mushroom business in Simtokha recently.

He said that he usually works at the weekend. He has prepared 200 bags and has sold around 80 at the cost of Nu 380 per bag so far. “Business is picking up.”

Chencho Thinley said his plan is to make 500 mushroom bags by the end of this year. His plan is also to grow shitake mushroom later this year.

“If we do the shitake business, we will get the product within six months. Shitake will be more sustainable because one billet can last around four years. Oyster bag won’t work after two and half months,” he said.

An official from the National Mushroom Centre in Wangchutaba said that the centre has been providing technical support to the growers.

He said that hygiene is very important. “Bacteria will affect the mushroom, especially in summer due to high temperature. To prevent bacteria, we provide organic liquefier.”

Edited by Jigme Wangchuk